Pattern Of A Grinding Ball

(PDF) Process Engineering with Planetary Ball

2013年2月7日 It gives examples of the aspects of grinding and illustrates some general guidelines to follow for modelling processes in planetary ball mills in terms of refinement, synthesis' yield and 2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy (PDF) Grinding in Ball Mills: Modeling and Process Control2009年10月1日 The objective of the work was to determine the grinding mechanisms in a stirred ball mill by using population balances The main grinding mechanisms are cleavage and some Identification of the grinding mechanisms and their origin in 2021年11月4日 grinding balls / media can be achieved It can be achieved that the grinding media are crossing the grinding jar and loosen from the wall At hitting the wall of the grinding PLANETARY BALL MILL Laarmann

Analysis of grinding kinetics in a laboratory ball mill using

2019年11月1日 First, the grinding parameters were calculated by applying size distributions of ground product under various conditions to PBM and the behaviors of the particles inside the 2003年5月7日 the basic pattern of motion of material in the mill The motion of an individual ball in the charge is complicated in practice and it is not possible to calculateTECHNICAL NOTES 8 GRINDING R P King Mineral Tech2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA ReviewGrinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical Grinding in Ball Mills: Modeling and Process Control

.jpg)

Enhancing the Grinding Efficiency of a Magnetite

2024年1月31日 Three grinding media approaches, including the utilization of steel balls, ceramic balls, and a hybrid combination, were investigated Through an analysis of the grinding kinetics and the R–R particle size characteristic 2018年1月1日 Grinding balls with 189 C131 Cr132 Mo136 V000051 B in ascast condition had the highest hardness, which was caused by finer structure of eutectic carbide, needle like structure (upper (PDF) Simulation for grinding balls production 2022年1月1日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power consumption and particle size breakage)Effect of grinding media on the milling efficiency of a ball mill2021年3月12日 in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications BALL MILLS Ball mill optimisation Holzinger Consulting

(PDF) Grinding Media in Ball MillsA Review Academia

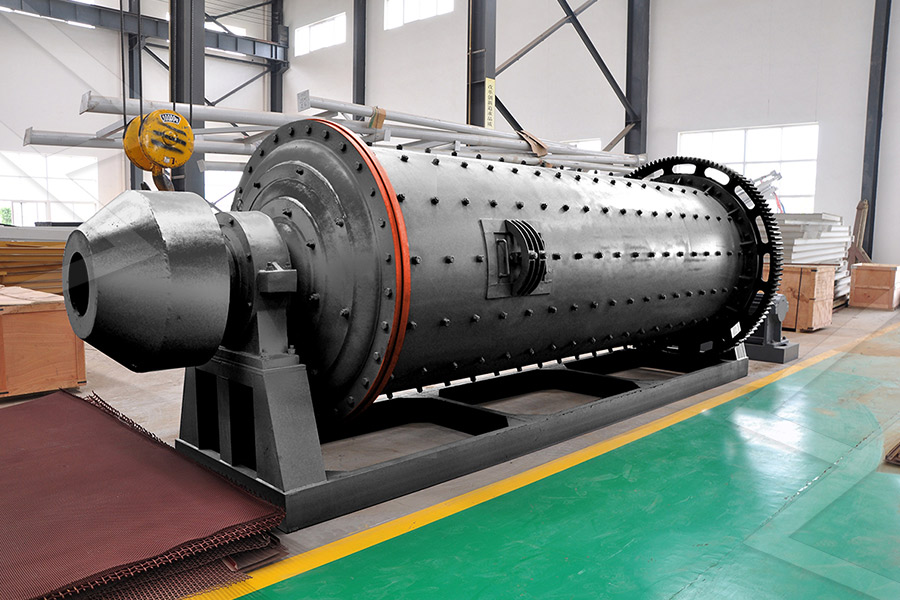

The grinding capacity, when using a mixture containing 25% pebbles, was the same as that with balls alone, resulting in a 13% saving in energy and an implied saving in ball consumption of 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the A Review of the Grinding Media in Ball Mills for Mineral 2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and (PDF) Grinding in Ball Mills: Modeling and Process Control2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of Morphology and wear of high chromium and austempered ductile iron balls

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented Abstract The paper presents an All of our grinding balls are readytouse and have been treated to remove residual oils and contaminants Related Products 28 mm Stainless Steel Grinding Balls 3 mm Stainless Steel Grinding Balls, Stainless Steel, 5/32'', Bottle of 年12月17日 The optimization of processing plants is one of the main concerns in the mining industry, since the comminution stage, a fundamental operation, accounts for up to 70% of Kinetics of DryBatch Grinding in a LaboratoryScale Ball Mill 2016年10月21日 GRINDING BALLS Grinding Balls are forged from the best highcarbon manganese steel and are nonbreakable These balls are of the very highest quality that can be produced, and give long, satisfactory service Cast Grinding Balls Rods 911Metallurgist

.jpg)

(PDF) Process Engineering with Planetary Ball

2013年2月7日 The present review focuses on the insight into several parameters like properties of grinding balls, the filling ratio or revolution speed Fig 2 Scheme of a ball motion pattern in a single 2021年4月27日 Condition in one of the grinding chambers of the mill Results of Optimization The graphical analysis presented in Figure 2 represents progress of grinding along the length OPTIMIZATION OF CEMENT GRINDING OPERATION IN 2020年7月2日 A properly seasoned charge of grinding media should be able to break large particles and not produce unnecessary ultrafine particles In recent research done by (PDF) Effects of Ball Size Distribution and Mill Speed and 2024年2月22日 Introduction In industrial processes, grinding balls are indispensable components in milling and grinding operations, where they play a pivotal role in reducing Ceramic vs Steel Grinding Balls: A Comprehensive

What is the heat treatment of grinding balls?

2024年8月19日 Heat treatment of grinding balls is a crucial process that enhances their performance and longevity Here's a general overview: 1 Austenitizing Purpose: To transform 2024年2月2日 To achieve high efficiency and low damage processing of ZrO 2 ceramic ball valves, a method for the cupshaped composite grinding wheel of ultrasonic vibration grinding Research on ultrasonic grinding ZrO2 ball valve with a cup 2022年8月10日 Causes of failure of grinding balls with diameter 110 mm produced traditionally by forging, quenching and lowtemperature tempering are considered The chemical Analysis of Failure of Grinding Balls During Service2015年1月1日 The results have shown that the ball movement regime for good grinding efficiency of the planetary ball mill is “cascading” or light “cataracting”, and contact forces have (PDF) Analysis of grinding force of a planetary ball mill by

(PDF) Effects of Ball Size on the Grinding Behavior of Talc Using

2019年10月31日 after 10 min of grinding with 2 mm and 1 mm balls and after 60 min of grinding with 01 mm balls, respectively Furthermore, similar specific surface areas of 1658, 1716, 2024年11月3日 A fabric ball pattern – what a great way to use up fabric scraps and make something playful! Now you can learn how to sew a ball or fabric sphere, and with a simple free ball sewing pattern to follow, you can make Free Fabric Ball Pattern (Sphere Template PDF)2017年4月29日 In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to its weight and velocity; then, Grinding Media Wear Rate Calculation in Ball Mill2024年3月19日 Abstract—For rolling of balls, one of the main parameters for both calculating passes and developing a model for a roll is the roll spacing at the crossing point (zones where Tuning Parameters of a BallRolling Mill for Rolling of Grinding Balls

.jpg)

The Effect of Grinding Media on Mineral Breakage Properties

2021年12月11日 22 Grinding Test In this paper, the wet ball milling process was used in the laboratory ball milling test Before grinding, the ball mill was kept idle for 10 minutes and then 2019年11月1日 For example, Mori et al studied the correlation between impact energy and grinding rate for a wet ball mill and reported that the grinding rate can be predicted through the Analysis of grinding kinetics in a laboratory ball mill using Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical Grinding in Ball Mills: Modeling and Process Control2015年6月19日 We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media 911 Metallurgist is a Mill Steel Charge Volume Calculation 911Metallurgist

Analysis of the main trends in the development of the

2020年8月13日 Therefore, a new mode of rolling grinding balls from the rejects of K76F rail steel was developed, which provides an increase in impact resistance of grinding balls while 2023年2月16日 Steel grinding balls are made from lowalloy steel and highcarbon steel The highcarbon steel balls are harder and more wearresistant, making them ideal for highimpact What are grinding balls made of?2018年1月1日 Grinding balls with 189 C131 Cr132 Mo136 V000051 B in ascast condition had the highest hardness, which was caused by finer structure of eutectic carbide, needle like structure (upper (PDF) Simulation for grinding balls production 2022年1月1日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power consumption and particle size breakage)Effect of grinding media on the milling efficiency of a ball mill

.jpg)

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications The grinding capacity, when using a mixture containing 25% pebbles, was the same as that with balls alone, resulting in a 13% saving in energy and an implied saving in ball consumption of (PDF) Grinding Media in Ball MillsA Review Academia2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the A Review of the Grinding Media in Ball Mills for Mineral 2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Morphology and wear of high chromium and austempered ductile iron balls

2021年11月1日 High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of 2012年6月1日 An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented Abstract The paper presents an Grinding in Ball Mills: Modeling and Process ControlAll of our grinding balls are readytouse and have been treated to remove residual oils and contaminants Related Products 28 mm Stainless Steel Grinding Balls 3 mm Stainless Steel Grinding Balls, Stainless Steel, 5/32'', Bottle of 年12月17日 The optimization of processing plants is one of the main concerns in the mining industry, since the comminution stage, a fundamental operation, accounts for up to 70% of Kinetics of DryBatch Grinding in a LaboratoryScale Ball Mill